PRODUCTS & SERVICES

Coating

Coating pretreatment / lubrication type phosphating Functional paint Painting auxiliary products

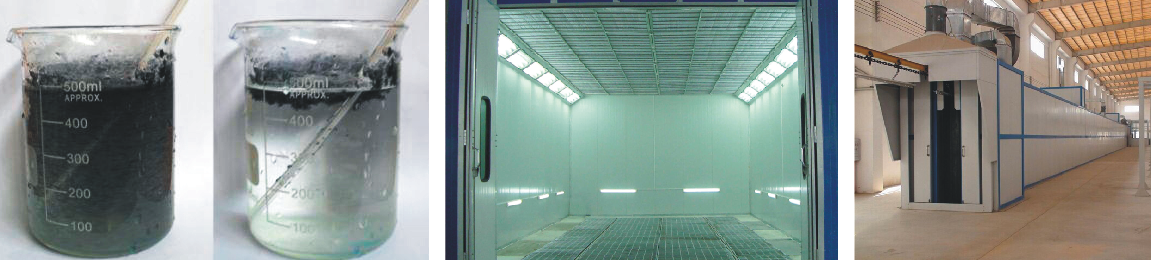

High-quality paint, electrostatic powder and electrophoretic coating cannot be separated from high-quality pretreatment.Modern coating more emphasis on environmental protection, energy efficiency and other production costs and social environment-friendly indicators of painting pre-treatment chemicals. WECAN provides the most comprehensive cleaning and conversion film products for plastics, steel, stainless steel, aluminum alloy, magnesium alloy and zinc alloy, so that the coating is more firmly combined with the workpiece to prevent corrosion under the coating and prolong the service life, realizing continued add-value for your products.

|

Product Category |

Use & Characteristics |

|

Plastic cleaning |

They are specifically designed for pre-cleaning of plastic surfaces for bonding or painting. They can clean the internal and external release agents of flexible plastic products to GM 9984801 (for plastic bumper).

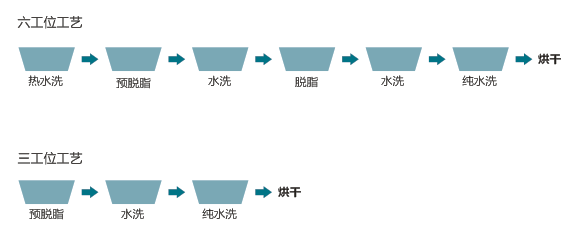

Hot water wash-Pre-degreasing - Water wash - Degreasing - Water wash– Pure water wash – Drying

Three-station process |

| Pretreatment of steel and polymetallic coating |

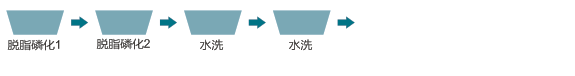

Iron phosphate is a kind of light alkaline earth metal phosphating solution, which treats blue-yellow phosphating film, degreasing phosphating two-in-one process. It is suitable for cold-rolled sheet, aluminum and galvanized sheet.

Degreasing phosphating 1 - Degreasing phosphating 2 – Water wash – Water wash Zinc Phosphating is a modified ternary low zinc phosphating process agent that can be used for phosphating treatment of steel plates and galvanized sheets. The dense phosphating film crystals are excellent in paint, powder coating and electrophoresis processes to meet the processing requirements of automobile body and various components.

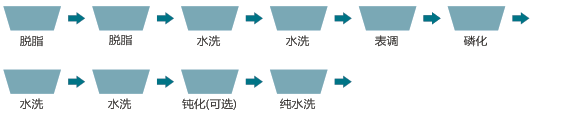

Degreasing - Degreasing - Water wash – Water wash –Surface conditioning - Phosphate– Water wash - Water wash –Passivation (Optional) – Pure water wash Phosphorus-free conversion coating Silane products, multi-purpose coating pretreatment agent Suitable for cold-rolled plate, galvanized sheet, aluminum, magnesium and zinc alloy. Can replace the zinc phosphating and chromium process, does not contain harmful metals. Almost no residue. Used in bath solutionat room temperature.

Degreasing - Degreasing - Water wash –Pure water wash – Silane - Pure water wash – |

| Pretreatment of aluminum and magnesium alloy coating |

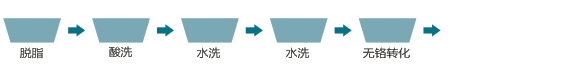

Chrome-free conversion coating , commonly used inpre-treatment of aluminum alloy powder, paint. With long bath solution life, easy maintenance, low consumption, it has passed AAMA test.Where the following process is powder spray, there’s no need for water wash.

Degreasing – Pickled - Water wash –Water wash –Chromium-free conversion- |

|

Manganese-based phosphating |

The manganese-based phosphating is used for iron to reduce sliding friction and improve the wear resistance of the active parts. The manganese phosphate film is 7-30 g / m2, conforming to DIN 50942.

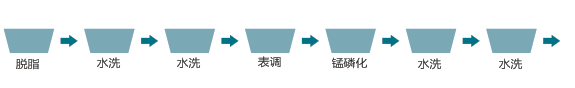

Degreasing –Water wash – Water wash - Surface conditioning - manganese phosphating – Water wash – Water wash - |

|

Electrolification |

It is an electroless phosphating product that does not contain heavy metals and is suitable for wire production processes that require cold forming, meaning, phosphating while online drawing. Steel wire substrate can be high, low carbon steel wire, fastener wire, or stainless steel wire. The thickness of the phosphating film can be precisely adjusted by the strength of the current and the processing time.

Mechanical rust remover – Electrolification – Water wash |